[17.1]

[17.1]

by

In 1953 at the Faculte de la Pharmacie de Nancy it was discovered that an organic materials could display electroluminescent properties with alternating current (AC). Ten years later, in 1963 Pope et al (at New York University) demonstrated the same thing with direct current (DC). The material he based his discovery on was anthracene, however this had high operating voltages and low quantum efficiency and thus failed to attract any attention [1]. Then in 1987 Tang and VanSlyke (at Eastman Kodak) made significant progress in the field by lowering the operating voltages and substantially increasing efficiency using the organic crystal hydroxyquinoline aluminium. The real breakthrough came in 1990 when Jeremy Burroughes, Richard Friend and Donal Bradley discovered that by if they put a small voltage through a plastic called ppv, a yellow green light was emitted [2]. Thus the problem of high voltages had been overcome but the efficiency was still very low, less than 0.01 per cent. By making changes to the structure and composition of the polymer, the efficiency was increased to 5 per cent bringing it into range of conventional LED (light emitting diodes) [3]. Realizing the commercial significance of their discovery they patented it and set up the company, Cambridge Display Technology in order to develop their product for commercial use [2].

A polymer is a natural or synthetic

compound, usually of high molecular weight consisting of many

repeating units of a simple molecule [4].

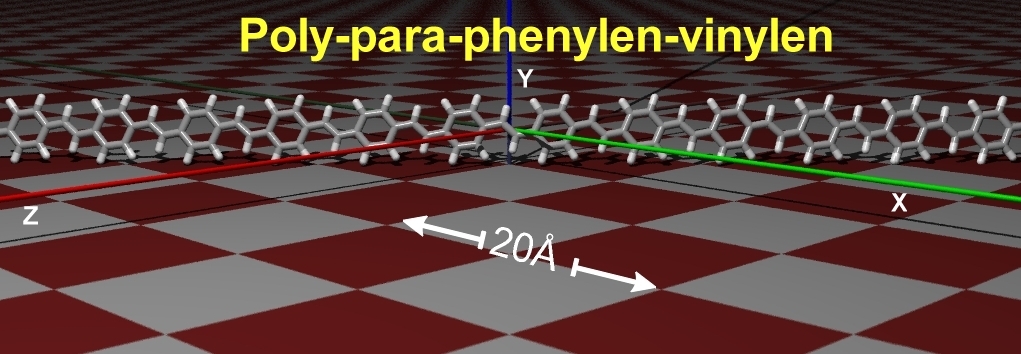

The polymer being considered is

poly[p-phenylene vinylene] below is an example of a repeating

unit.

The alkene component is made up of two carbon-carbon bonds, a s (sigma) bond and a p (pi) bond. The s orbital is made an end on overlap between two sp2 hybrid orbitals. A sp2 hybrid orbital is made by mixing one s orbital with two p orbitals to give three equivalent orbitals which exhibit one third s character and two thirds p character. The p bond is made by a side on overlap between adjacent p orbitals, as carbon has three p orbitals and has only used two in forming its hybrid orbitals its third p orbital is free to form a p bond.

The conductivity can be explained by looking at what happens to the energy of molecular orbitals.

The above diagram shows that as the number of molecular

orbitals increases, they get closer together and eventually

converge into two bands within which the MO (molecular orbital)

spacing is so small it can be regarded as a continuum rather

than discreet energy levels. The space between the two

energy bands is called the band gap and represents the energy

required to promote an electron from the highest occupied

molecular orbital (HOMO), to the lowest unoccupied molecular

orbital (LUMO). The diagram below shows this more

clearly.

The valence band represents the p band and (the bonding orbitals) and the conduction band represents the p* band (the anti bonding orbitals). By applying an electric field electrons can become excited and move from the valence band to the conduction band, and hence carry current [8]. Thus the band gap is an important factor in determining the conductivity of a material.. Metals (such as Cu or Pt) have very small or no band gaps, semi conductors (such as Si or Ge) have band gaps ranging from about 0.1 eV [8] to about 5 eV [9] above which materials are regarded as insulators (such as C in the diamond form). PPV has a band gap of 2.2 eV [1]. Photon energies of 1.5 eV to 3.0 eV correspond to the visible part [8] of the electromagnetic spectrum. So when a electron is excited to the conduction band, it must eventually decay back to the more stable valence band, emitting energy (2.2 eV) in the form of a photon, which being in the visible part of the spectrum results in the electroluminescence seen. The wavelength of the photon can be calculated using the following equation:

E = hn = (hc)/l

Where: E = 3.5248 x 10-19 ( 1

eV = 1.6022 x 10-19 J ) [10]

h = 6.6262 x 10-34 j s (planck constant) [10]

c = 2.9979 x 108 m s-1 (speed of

light) [10]

all numerical values are quoted correct to 5 significant figures.

Evaluating this equation gives l = 563 nm. A wavelength of 563 nm corresponds to a yellow-green (580-530nm) [10] luminescence of light. The complete electromagnetic spectrum is shown below.

The wessling method is the most common method used in the production of ppv. The synthetic precursors used is p-Xylylenebis(tetrahydrothiophenium chloride), and is available from Sigma Aldrich [13]. Another synthesis route can view at http://www.furman.edu/~hanks/ntc/PolySynth2.html.

Polymers in general have had a major significance in commercial applications since their discovery and today one could not possibly imagine a world without polymers in there conventional application as plastic, they are known to be cheap, mouldable materials of varying strength. But now polymers potentially have a much wider range of uses, the ability of conjugated polymers to to conduct electrical current could bring both technical and economic benefit leading to their use in countless applications world-wide. Advantages over conventional conductors include, insensitivity to mechanical shock and electromagnetic pickup, their flexibility, toughness, and capacity to be easily processed in large area, thin films of practically any shape make them a tempting alternative [15]. As stated above conductive polymers such as ppv also have even further applications through there electroluminescence, they can be manipulated to create flat, thin, display screens for television, telephones and thousand of other applications discussed later. The development of ppv to create viable commercial products is outlined below.

When a thin layer of ppv is sandwiched between an anode and a cathode, as shown in the diagram below, and a small positive potential is applied the ppv glows.

By using this fact it is possible to adapt this applications

to larger light emitting displays, and by using different

derivatives of ppv different colours can be obtained, making

full colour displays possible through mixing the three primary

colour (red, blue and green). Below are examples of the

variety of colours possible by using different derivatives of

ppv.

The passive matrix drive and the active matrix drive were also both developed. In the passive matrix drive a glass surface is coated with a conductive material, a series of grooves are etches into the material which are called the anode lines. A thin layer of the polymer is applied to the substrate and on to this another set of lines, the cathode lines are applied perpendicular to the anode lines. When the appropriate voltage is applied to an anode line each cathode line becomes activated in sequence then the next anode line followed by the cathode lines in sequence and the cycle repeats itself.. The result is each row of pixels illuminates for a short period of time. The active matrix drive gives brighter more defined images but all this comes at a cost. The active matrix is similar but each pixel has two transistors built into the matrix which can hold a pixel in the on state [18].

The applications of such a diverse material could be endless and look set to become a integral part of everyday life and soon with some companies claiming to have them commercially available by 2002 (that's this year!) [19]. The introduction of OLEP (organic light emitting polymer) displays would bring a whole new dimension to the craze for flat screen plasma television and flat screen monitors, being thinner, lighter, more robust, flexible and having a wider viewing angle (180o) [3]. But their usefulness would go beyond traditional applications, due to their amazing combination advantages over existing displays, they could be used in mobile telephones, palmtops, watches, billboard posters, even clothing is possible. The advent of OLEP displays could mark a turning point in the twenty-first century and it is possible that over the next twenty years they will be common place in the world around us.

Prototype of a high resolution, full colour passive matrix

PolyLED display, fabricated by inkjet printing [20].

Photo: Philips Research

A 64 x 64-pixel Polymer-Dispersed Liquid-Crystal Display

(PDLCD) display driven by an active matrix of polymer-based

thin-film transistors (TFTs). The display has a size of 3.5

by 3.5 cm2. The image contains 256 grey levels; the display

is refreshed at 50 Hz [20].

(See also publication in Nature, December 6, 2001)

Photo: Philips Research

Flexible 6-inch polyimide foil with a variety of components

and electronic test circuits. The circuits still operate when

the foil is sharply bent [20].

Photo: Philips Research

Many online sources of information were used in the compilation of this project. The search engines were the first port of call, a couple had very little if any information but google found a lots of sites with relevanent material and tons that had nothing to do with the subject, but overall was very helpful. After the online search I turned to more traditional sources of information, using the Libertas catalogue I found numerous books related topics. I have awarded stars to each reference taking into account suitability and ease of use (max. five *)

[1] Building

Light Emitting Devices Based on Polymeric

Substances **

http://www.physics.ohio-state.edu/~reu/00reu/final_pdf/sarp.pdf

[2] BBC

News

***

http://news.bbc.co.uk/hi/english/sci/tech/newsid_390000/390220.stm

[3] Cambridge Display

Technology

**

http://www.cdtltd.co.uk/

[4] Wordsmyth, the educational

dictionary

thesaurus

***

http://www.wordsmyth.net/

[5] Conjugated

Polymers: Electronic

Conductors

**

http://mmrc.caltech.edu/colin/science/past/PhD/html-thesis/node8.html

[6] Electronic

Properties of

Polymers

**

Donald A. Seanor

[7] Electronic

Properties of

Solids

***

Professor Tim

Jones

[8] The

Electronic Structure and Chemistry of

Solids

****

P. A. Cox

[9] Basic Solid

State

Chemistry

**

Anthony R. West

[10] Physical

Chemistry

***

P. W. Atkins

[11] The

Electromagnetic

Spectrum

****

http://fuse.pha.jhu.edu/~wpb/spectroscopy/em_spec.html

[12] Highly

Conjugated

Polymers

****

http://www.chem.umass.edu/~lahti/Conjpoly/conjtxt.htm

[12.1] F.R. Denton, III, P. M. Lahti, F.E. Karasz, "The Effects of Radical Trapping Reagents Upon Formation of Poly(alpha-Tetrahyrothiophenio-Para-Xylylene) Poly electrolytes by the Wessling Soluble Precursor Method", J. Polym Sci. A. Polym. Chem. SO. 2223-2232 (1992)

[13] Sigma

Aldrich

**

http://www.sigma-aldrich.com/aldrich/brochure/al_pp_electronic.pdf

[14] Redox

Polymers as

Chromophores

***

http://www.furman.edu/~hanks/ntc/PolySynth2.html

[15] Ency of Physical Science and Technology (Acad. Press) ***

[16] Sogang

University

***

http://www.sogang.ac.kr/~sgpolym/LEDPicture1.htm

[17] Covion

Organic Semiconductors

Gmbh

***

[17.1]http://www.covion.com/technology/chemistry.html

[17.2] http://www.covion.com/ny-slides/sld016.htm

[18] Uniax

Polymer

Electronics

***

http://www.uniax.com/

[19] China

Telecom

*

http://www3.chinatelecom.com.cn/20011127/00000286.html

[20] Philips

Research

**

http://www.research.philips.com/pressmedia/releases/9802e.html

[21]

Beilstein

Commander

no stars!

http://www.ch.ic.ac.uk/local/it/cross.bsd

[22] Google

Search

Engine

****

http://www.google.com/

[23]

RCS

**

http://www.rsc.org/is/journals/current/ejs.htm

[24]

WOS

**

http://wos.mimas.ac.uk/

[25]

Libertas

*****

http://www.lib.ic.ac.uk/catalogue/cataccess.htm

[26] K. Amili, P.

Molinie, N. Blel, J.L. Fave, J.C. Bernede, M. Ghedira,

"Synthesis and cheracterization of C1-4

poly-phenylene-vinyl-ether photoluminescent copolymers",

Synthetic metals, May

2000

****

www.elsevier.com/locate/synmet

[27] J.H. Burroughes, D.D.C. Bradley, A.R. Brown, R.N. Marks, K. Mackay, R.H. Bum, Nature 347 (1990) 539

[28]

www.sciencedirect.com

****

www.sciencedirect.com

[29]

Corina

****

http://www2.chemie.uni-erlangen.de/software/corina/corina.html